Forged ball valves, on the other hand, are manufactured through the forging process, where metal iscompressed and shaped under high pressure. This results in a more robust and compact structure, makingforged ball valves ideal for high-pressure and high-temperature applications. The forging processenhances the mechanical properties, providing increased strength and resistance to mechanical stresses.

Praesent ac sem eget est egestas volutpat. Vestibulum dapibus nunc ac augue. Nulla neque dolor, sagittis eget, iaculis quis, molestie non, velit. Phasellus viverra nulla ut metus varius laoreet. Suspendisse nisl elit, rhoncus eget, elementum ac, condimentum eget, diam.

Design Features

• Valves designed according to API 6D

• All sizes available as full- or reduced bore

• Double block-bleed on request

• Fire safe to BS 6755, API 6FA and API 607

• Valve seats as single or double piston type

• Elastomeric and thermoplastic sealing materials to suit

application

• Can be delivered with any type of actuator & accessories

• Secondary sealing by grease injection

• All sizes and classes available with metal-metal sealing

• Fully welded upon request

• Antistatic device and anti blow-out stem

• Special executions for cryogenic or high temp service

Floating Ball / Trunnion Mounted Ball

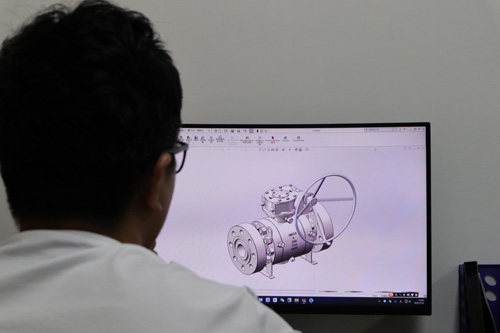

Floating ball and trunnion mounted designs are the two main types of forged ball valves.

The floating ball design allows the ball to move slightly under line pressure, pressing against the downstream seat for reliable sealing. It is well-suited for small to medium-sized valves in low and medium-pressure systems, offering cost efficiency and dependable shut-off.

In contrast, trunnion mounted ball valves anchor the ball at both ends, reducing torque requirements and ensuring reliable sealing under high pressure. This design is preferred in large-diameter pipelines and heavy-duty oil & gas applications.

At CARILO, both floating and trunnion mounted forged valves are engineered with precise tolerances, strict testing, and long service life to meet international standards.

The Number of Body Pieces- TWO/ THREE

Body construction directly impacts maintenance and performance.

Two-piece forged ball valves feature a compact design, providing strength and cost-effectiveness. They are widely applied in industries where durability and simple operation are required, such as petrochemical processing and energy systems.

Three-piece forged ball valves are designed for easier servicing. The middle section containing the ball and seats can be removed without disconnecting the valve from the pipeline. This makes them ideal for applications that require frequent cleaning, inspection, or replacement.

CARILO manufactures both two-piece and three-piece valves with advanced forging technology, ensuring superior material strength, safety, and operational efficiency.

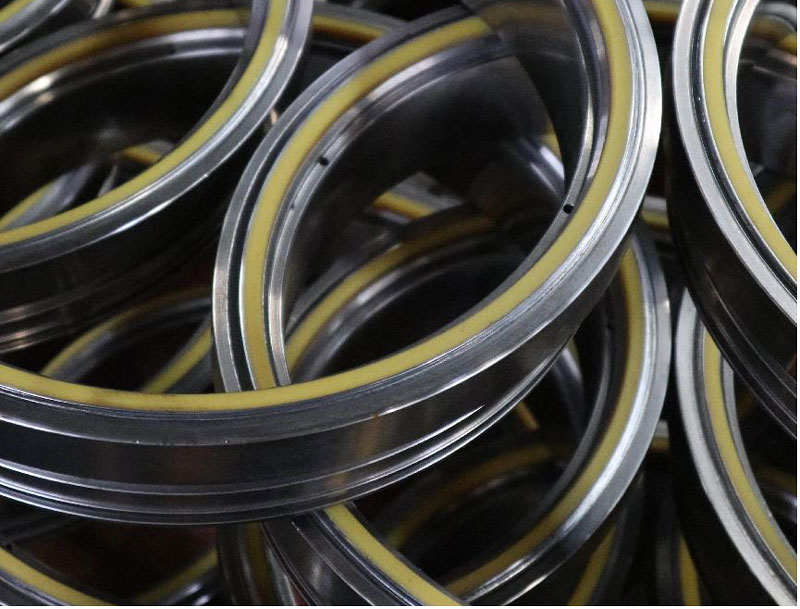

Soft seated / Metal seated

Seat material defines the working limits of forged ball valves.

Soft-seated valves use materials such as PTFE, providing bubble-tight shut-off and low operating torque. They are ideal for clean media like natural gas and refined fluids in moderate temperature and pressure conditions.

Metal-seated valves, however, are built for harsher service. With special coatings and hard-facing, they can withstand extreme heat, abrasive particles, and corrosive media. This makes them suitable for refineries, petrochemical plants, and high-cycle industrial operations.

CARILO offers both soft-seated and metal-seated solutions, manufactured to API, ASME, and ISO standards. Our team helps customers select the right configuration for their unique operating environment.

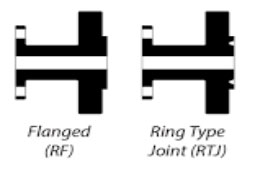

The types of end connection - RF/RTJ/SW/BW/NPT

RF (Raised Face):

Commonly used for flanged connections, providing secure sealing and easy alignment.

RTJ (Ring Type Joint):

Ideal for high-pressure applications, ensuring robust sealing with metal-to-metal contact.

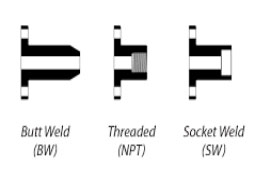

SW (Socket Weld):

Suitable for welded connections, offering reliable joint integrity and reduced stress concentration.

BW (Butt Weld):

Perfect for pipeline connections, ensuring strong and leak-resistant joints.

NPT (National Pipe Thread):

Versatile threaded connections, easy to install and suitable for various applications.

Different Design - DBB/ DIB-1/ DIB-2

DBB (Double Block & Bleed):

Provides reliable isolation and double block capabilities, ensuring enhanced safety in critical processes.

DIB-1:

DIB-1 ball valves have DPE seats both upstream and downstream to provide a seal in both directions. For the DIB-1 configuration, over pressurization of the cavity is avoided by the use of an external relief valve. With the ball in the closed position and pressure on the upstream side, the cavity pressure will increase in case of upstream seat failure. The cavity pressure will cause a double piston effect on the downstream seat creating a second seal on the ball.

DIB-2:

For the DIB-2 configuration, one seat SPE and the other DPE, cavity over-pressurization is internally controlled within the line. If the upstream seat leaks, then there is automatic cavity pressure relief on the upstream side and the downstream seat will provide isolation due to double piston effect.

View More About Forged Ball Valves

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a tall container of products:

What is the difference between a soft seat and a metal seated ball valve?

It was a conversation that brought together two minds, mine from CARILO and the brilliant folks at one of oil&gas companies. In the heart of it was a cautionary tale – a reminder that even

Training of department heads

In order to expand our knowledge in valve technology and operate our plant in an efficient way. CARILO offers training in valve technology to further qualify our team.

Why Use A 3 Piece Ball Valve?

Hey there, my guys! This is Eric. As the Valve Engineer of the Technical Department at CARILO Valve Co., Ltd., I’m thrilled to chat with you about the wonders of 3-piece ball valves. If you’re

The Distinction between DBB& DIB Valves

API 6D calling out the distinction between a double block and bleed valve and a double isolation and bleed valve. But I do not think this distinction is properly recognized by the whole valve industry. we still see many technical documents

Bronze Valve Specialist

Zhejiang Carilo valve Co., Ltd. is one of the top bronze valve manufacturers in China.The material of Bronze has characteristics of low melting point, high hardness, plasticity, and wear resistant, corrosion resistance. So bronze valves

20th anniversary celebration

Our experience as a manufacturer of industrial valves has enabled us to reach the most demanding customers. One of our main values is the satisfaction of our customers and the efficiency of our products. Now

Customer Factory Inspection

The customer from Russia knew us through one of the world’s top steam management system manufacturers and simply came to visit and inspect our factory.They said that in 20 years in the industry, they had

Our valves are successfully installed in project units

Our General Manager Ethan Chou visited our South East Asia agent and was fortunate enough to see our ball valves being successfully installed on the complete machine. After passing the test they will being shipped

OGA 11-13 July 2017, Malaysia

OGA 2017 will take place from July 13-15 at Kuala Lumpur Convention Centre, marking its 16th edition as Southeast Asia’s largest trade show for the oil, gas and petrochemical engineering industry. Since 1987, OGA has

Training of API internal auditors Q1

As a manufacturer specializing in the production of API Standard products, it is necessary to deepen the content of API, so we appoint our technical department staff to attend the training of API internal auditors

Order & Payment

Most Popular Questions

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Sit tristique montes adipiscing ipsum sociosqu inceptos fusce tempus. Cubilia consectetuer tortor quam dictum integer arcu lectus feugiat sagittis. Litora id enim habitant aptent molestie erat.

Sit tristique montes adipiscing ipsum sociosqu inceptos fusce tempus. Cubilia consectetuer tortor quam dictum integer arcu lectus feugiat sagittis. Litora id enim habitant aptent molestie erat.

Sit tristique montes adipiscing ipsum sociosqu inceptos fusce tempus. Cubilia consectetuer tortor quam dictum integer arcu lectus feugiat sagittis. Litora id enim habitant aptent molestie erat.

Sit tristique montes adipiscing ipsum sociosqu inceptos fusce tempus. Cubilia consectetuer tortor quam dictum integer arcu lectus feugiat sagittis. Litora id enim habitant aptent molestie erat.

Sit tristique montes adipiscing ipsum sociosqu inceptos fusce tempus. Cubilia consectetuer tortor quam dictum integer arcu lectus feugiat sagittis. Litora id enim habitant aptent molestie erat.

Sit tristique montes adipiscing ipsum sociosqu inceptos fusce tempus. Cubilia consectetuer tortor quam dictum integer arcu lectus feugiat sagittis. Litora id enim habitant aptent molestie erat.

Send us a message

If you have any questions or would like to book a session please contact us.